Surface: optimising your adhesion

Successful, strong and reliable bonding and coating processes start with understanding your surface. Whether it’s adhesives, inks, sealants, paints, coatings, tapes… or barnacles, the effectiveness of adhesion is influenced by properties of the surface like cleanliness, roughness, and energy.

To help optimise adhesion, you will want to assess your substrate surface energy and cleanliness. If required, you can improve the substrate surface energy with some form of treatment. You can also select an adhesive material which can bond with a surface which is less than optimal.

Explore our range of materials, equipment and techniques to find the right approach for your surface.

|

|

Surface energy measurement

Understanding surface energy is critical to achieving strong and reliable bonds. Tools from Biolin Scientific and SITA Messtechnik enable you to analyse and quantify the surface energy of your substrates.

Surface energy, contact angle, and wetting measurements with these precise instruments will help you make informed decisions to enhance your adhesion.

Increase your surface energy

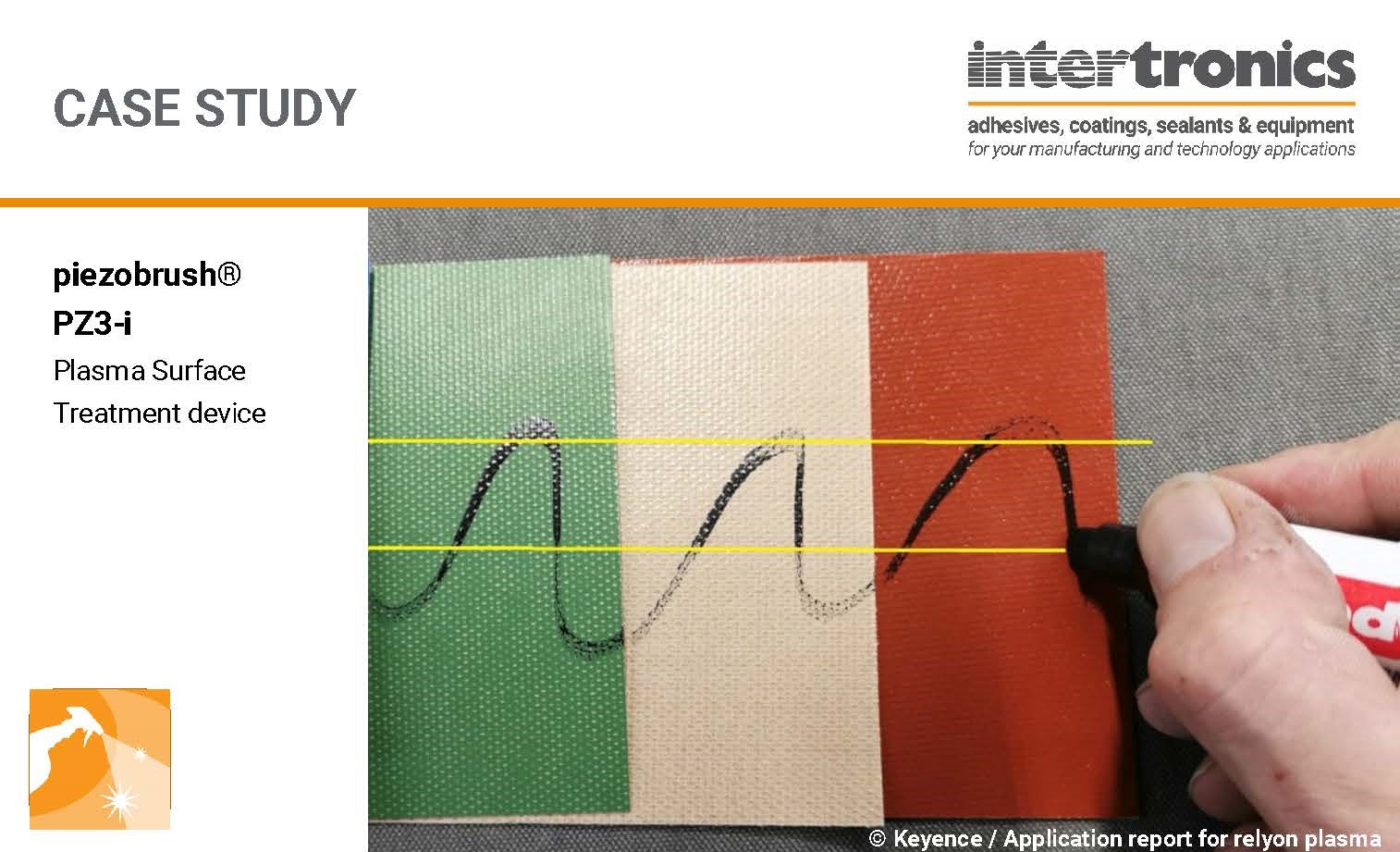

Boost the surface energy of your materials with plasma surface treatment. Using equipment like the piezobrush PZ3 from Relyon Plasma, you can modify surfaces at a molecular level, improving adhesion, wetting, and cleanliness. Whether you’re bonding, coating, or printing on low-energy plastics or other difficult-to-bond materials, plasma treatment can help to produce a more robust and durable bond.

Structural bonding of low surface energy plastics

SCIGRIP SG400LSE is formulated to deliver exceptional bonding performance for low surface energy plastics such as polypropylene, polyethylene, other polyolefins, and thermoplastic elastomers – overcoming the challenges associated with these substrates without the use of primers, and with little-to-no surface preparation.

Detect surface contamination

Contamination on a surface can significantly impact adhesion, coating performance, and overall product quality. Tools like the SITA CleanoSpector can assess the cleanliness of your part by checking for oil, grease, coolants, release agents, cleaning fluids and other organics.

Surface energy assessment

Need a quick and easy way to measure surface wetting or surface energy? Dyne Testing pens and inks provide an assessment in three seconds, allowing you to determine whether a substrate is above or below a specific surface energy. By using a range of Dyne Pens of various dyne levels, the surface energy of a substrate can be determined to a narrow range.

Surface preparation

Oils, dust, residues and other surface contamination can hinder adhesion and compromise your results. adhere IPA cleaning wipes provide a versatile and cost-effective way of cleaning your substrates prior to your bonding, coating or printing processes.

Surface energy go/no-go test

The Instant Test Pen – 38 Dyne allow you to measure the surface energy of your material. One quick test will identify if the surface is treated to a level of 38mN/m (Dynes/cm) or higher, quickly identifying the treated or non treated side of the material especially useful on polyethylene or polypropylene films after corona surface treatment.

“Instant” bonding with primer

You can get the benefits of cyanoacrylate adhesives CAs (single part, fast cure) for bonding polypropylene, polyethylene, silicone rubber and even PTFE (Teflon®). A cyanoacrylate primer improves the adhesion of cyanoacrylate adhesives to difficult to bond plastics and rubbers.

Further resources