SCIGRIP SG400LSE MMA Methyl Methacrylate Adhesive for Low Surface Energy Plastics, Polypropylene

About SCIGRIP SG400LSE MMA Methyl Methacrylate Adhesive for Low Surface Energy Plastics, Polypropylene

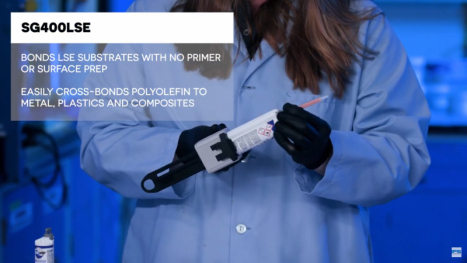

SCIGRIP® SG400LSE MMA Methyl Methacrylate Adhesive is a two-component 10:1 formulation tailored for bonding low surface energy plastics such as polypropylene, polyethylene, other polyolefins, and thermoplastic elastomers to metals, FRP and other plastics – without the use of primers, and with little to no surface preparation.

Its fast cure time and high initial tack facilitate efficient assembly processes, reducing production time and increasing overall productivity. Application of SCIGRIP 400LSE is simple, requiring minimal surface preparation due to its excellent wetting properties.

Capable of creating durable cross bonds with plastics, metals, and composites, it’s versatility extends across industries including automotive, electronics, signage, and assembly, where it excels in bonding components subjected to harsh environmental conditions and mechanical stresses.

The adhesive exhibits no sagging, maintaining stability even when applied vertically and boasts low exotherm properties, minimising heat generation during the curing process.

For ease of use, SCIGRIP SG400LSE is supplied in pre-measured, side-by-side double syringe cartridges and includes static mixing nozzles for straightforward application.

Features & Benefits

- Bonds polypropylene, polyethylene

- Bonds low surface energy plastics without primers or extensive surface preparation

- Primerless adhesion for most metals simplifies bonding processes

- Can replace hot air or heat welding of plastics

- Non-sag on non-level surfaces

- Creates durable cross bonds with plastics, metals, and composites

- Low exotherm properties, minimising heat generation during curing

- Fast cure time and high initial tack for an efficient assembly process

- Supplied in pre-measured, side-by-side double syringe cartridges for easy application

Specifications

| Specification | SCI SG400LSE-03-W |

|---|---|

| Colour | Off White |

| Mix ratio | 10:1 |

| Shelf life | 6 months |

| Cure schedule | |

| Working life | 3 minutes |

| Fixture time | 6 hours |

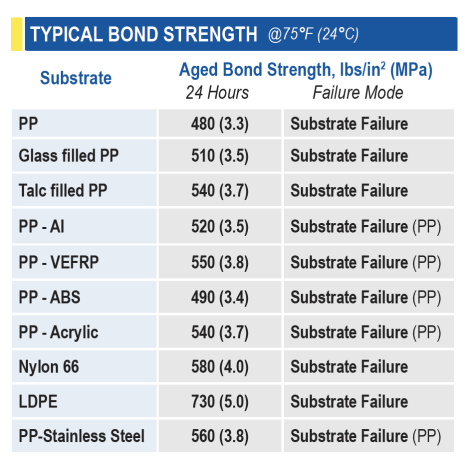

Typical bond strength

| Substrate | MPa | Failure Mode |

|---|---|---|

| PP | 3.3 | Substrate |

| Glass filled PP | 3.5 | Substrate |

| Talc filled PP | 3.7 | Substrate |

| PP – AI | 3.5 | Substrate (PP) |

| PP – VEFRP | 3.8 | Substrate (PP) |

| PP – ABS | 3.4 | Substrate (PP) |

| PP – Acrylic | 3.7 | Substrate (PP) |

| Nylon 66 | 4.0 | Substrate |

| LDPE | 5.0 | Substrate |

| PP – Stainless Steel | 3.8 | Substrate (PP) |

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Other Information

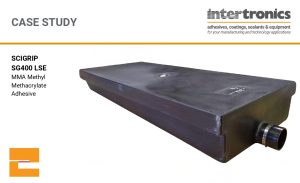

See how the SG400LSE works as part of a real application in this adhesive Case Study:

|

Bonding and sealing polyethylene tanks using MMA adhesive

A rotational moulding company producing LDPE tanks needed an effective way to repair blow holes in their polyethylene products. After consulting IPS Adhesives, they trialled SCIGRIP SG400LSE, a specialised adhesive for low surface energy plastics. Its successful application reduced waste, enhanced product quality, and achieved significant cost savings. |

| This Strength Test Report shows that SG400LSE can bond and hold strength on polypropylene and polypropylene to aluminium. All of the specimens in the lap shear test showed either substrate stretch or failed cohesively. | ||

| This Temperature Test Report shows that polypropylene lap shear strength decreases as the temperature increases, but the failure mode is consistent with substrate failure on all samples. The adhesive never failed in this test. Testing on Al shows that the adhesive still has reasonable strength at 80°C. | ||

| This UV Test Report shows the results of some QUV testing. All of the specimens failed by stock break after 100 hours of UV exposure. The strength was slightly lower, indicating that the polymer substrates were impacted by the UV exposure more than the adhesive was. There was no adhesive or cohesive failure observed in any of the specimens. | ||

|

Structural Adhesives Selector Guide

Start your adhesive selection process by reading our Structural Adhesives Selector Guide, detailing different chemistries and material specifications. |

|

|

|

|

- Last updated: February 2025

- Version: 1.5

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for their intended use and the user assumes all risk and liability whatsoever in connection therewith.

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _gat | 1 minute | This cookie is installed by Google Universal Analytics to restrain request rate and thus limit the collection of data on high traffic sites. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_JXM99Q99DB | 2 years | This cookie is installed by Google Analytics. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _hjAbsoluteSessionInProgress | 30 minutes | Hotjar sets this cookie to detect the first pageview session of a user. This is a True/False flag set by the cookie. |

| _hjFirstSeen | 30 minutes | Hotjar sets this cookie to identify a new user’s first session. It stores a true/false value, indicating whether it was the first time Hotjar saw this user. |

| _hjIncludedInPageviewSample | 2 minutes | Hotjar sets this cookie to know whether a user is included in the data sampling defined by the site's pageview limit. |

| _hjSession_1926691 | 30 minutes | No description |

| _hjSessionUser_1926691 | 1 year | No description |

| _hjTLDTest | session | To determine the most generic cookie path that has to be used instead of the page hostname, Hotjar sets the _hjTLDTest cookie to store different URL substring alternatives until it fails. |

| Cookie | Duration | Description |

|---|---|---|

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |