SCIGRIP SG300 MMA Methyl Methacrylate Adhesive, 10:1

About SCIGRIP SG300 MMA Methyl Methacrylate Adhesive, 10:1

SCIGRIP® SG300 MMA Methyl Methacrylate Adhesive is a two-component structural methacrylate adhesive for bonding metals, composites, and plastics without the use of primers and with little to no surface preparation. A strong candidate for applications where the risks of vibration and impact are prevalent, its resiliency allows this adhesive to withstand impact and vibration stresses, whilst maintaining bond line strength.

SCIGRIP SG300 is our very popular “workhorse” 10:1 MMA structural adhesive, finding applications in transportation, marine, product assembly and infrastructure projects. By offering a combination of strong bonding properties, ease of use, and versatility across materials, SG300 provides an efficient and effective solution for various structural bonding needs in industrial applications.

Developed to meet specific requirements of the transport industry, SCIGRIP SG300 is designed to offer reduced read through on show surfaces made from thin gauge metals, removing post finishing requirements and boosting aesthetics. SG300 is certified to EN45545-2 2013, the European safety standard for Fire, Smoke and Toxicity (FST) for use in rail construction. It has DNV and Lloyd’s Register approvals for ship building and has been tested for long-term undersea applications.

SCIGRIP SG300 is supplied in pre-measured, side-by-side double syringe cartridges and includes static mixing nozzles for straightforward application.

Features & Benefits

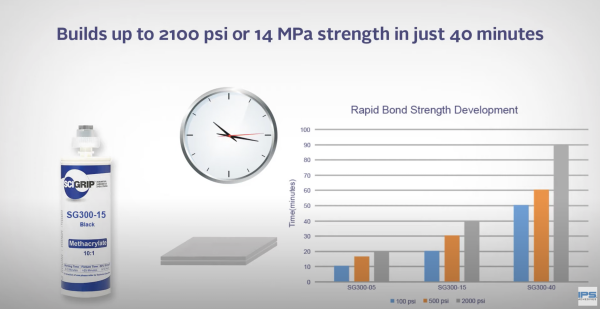

- Choice of 5 and 15 minute working times

- Very fast cure time, in a “hockey stick” profile

- Excellent fatigue, impact and shock load resistance

- Reduced bond line read through results in fewer post finishing processes

- Outstanding environmental resistance in harsh operating environments

- Primerless adhesion for most metals simplifies bonding processes

- Non-sag on non-level surfaces

- Gap filling up to 9.5mm

- Salt water corrosion resistance

- Tested for long-term undersea use

Applications

Primerless metal bonding (Al, steel, coated metals)

Primerless metal bonding (Al, steel, coated metals)- Composite bonding (epoxy, vinyl esters, gelcoats, polyester, etc)

- Plastic bonding (ABS, acrylics, PVC, etc)

- Rail carriage applications, vertical and horizontal surfaces, cavities, dashboards, luggage storage compartments and gangways

- Marine window bonding

- Automotive panel bonding

Specifications

| Specification | SCI SG300-05-B | SCI SG300-15-B |

|---|---|---|

| Colour | Black | Black |

| Mix ratio | 10:1 | 10:1 |

| Shelf life | 9 months | 9 months |

| Cure schedule | ||

| Working life | 5 minutes | 15 minutes |

| Fixture time | 17 minutes | 35 minutes |

| Cured properties Measurements taken at 24°C |

||

| Tensile strength | > 12 MPa | > 12 MPa |

| Tensile modulus | > 276 MPa | > 276 MPa |

| Lap shear strength | > 16 MPa | > 16 MPa |

| Elongation at break | > 40% | > 40% |

| Operating temperature range | -40°C to 82°C | -40°C to 82°C |

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Selector Guide

| Substrate | Recommended | Test | Primer recommended |

Surface preparation recommended |

|---|---|---|---|---|

| Metals | ||||

| Aluminium | ||||

| Coated/Painted metals | ||||

| Plated metals | ||||

| Sheet metal | ||||

| Cold rolled steel | ||||

| Thermoplastics | ||||

| ABS | ||||

| Acrylics | ||||

| Polycarbonates | ||||

| Vinyls (PVC) | ||||

| Thermoset Composites | ||||

| Fiberglass | ||||

| Gelcoats | ||||

| SMC & BMC | ||||

| RTM & RTM light |

Other Information

|

Structural Adhesives Selector Guide

Start your adhesive selection process by reading our Structural Adhesives Selector Guide, detailing different chemistries and material specifications. |

|

Adhesive Problem? What’s the Cure?

A guide to adhesive bonding, considering structural bonding and the criteria involved for successful assembly. |

All Downloads

Ordering Information

|

|

|

- Last updated: October 2024

- Version: 1.5

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.