Category: plasma

Getting under the surface of surfaces

Successful, strong and reliable bonding and coating processes start with understanding of adhesion, and that means understanding your surface. No matter what you’re bonding, the effectiveness of adhesion is influenced by properties of the surface like cleanliness, roughness, and energy. Since acquiring Dyne Testing Ltd, our interest in – and understanding of – surface science […]

Read More

What is wetting? – a JoinedUpMinute overview

Our final JoinedUpMinute for 2024 is a speedy overview of wetting, courtesy of Alison. She explains: What wetting is and why it’s important How wetting relates to surface energy How to improve wetting Check it out! If you want to dive deeper into how to improve wetting, have a look at our video How […]

Read More

What does plasma do to a surface? JoinedUpMinute with Craig Geerthsen

In this week’s JoinedUpMinute video, Craig provides an overview of what plasma surface treatment accomplishes. You’ll learn: What is plasma? What are the various benefits of plasma in surface treatment? Check it out! For more information about improving surface treatment with plasma, here are some further resources: Video: How does plasma surface treatment improve adhesion? […]

Read More

How plasma surface treatment improves print quality

Some high-performance plastics pose a problem during printing — their low surface energies make high-quality, reliable printing challenging. So, how can manufacturers address this challenge, and what can we learn from real life applications? Here we discuss the use of plasma surface treatment for printing onto low surface energy plastics. Wetting is a prerequisite of […]

Read More

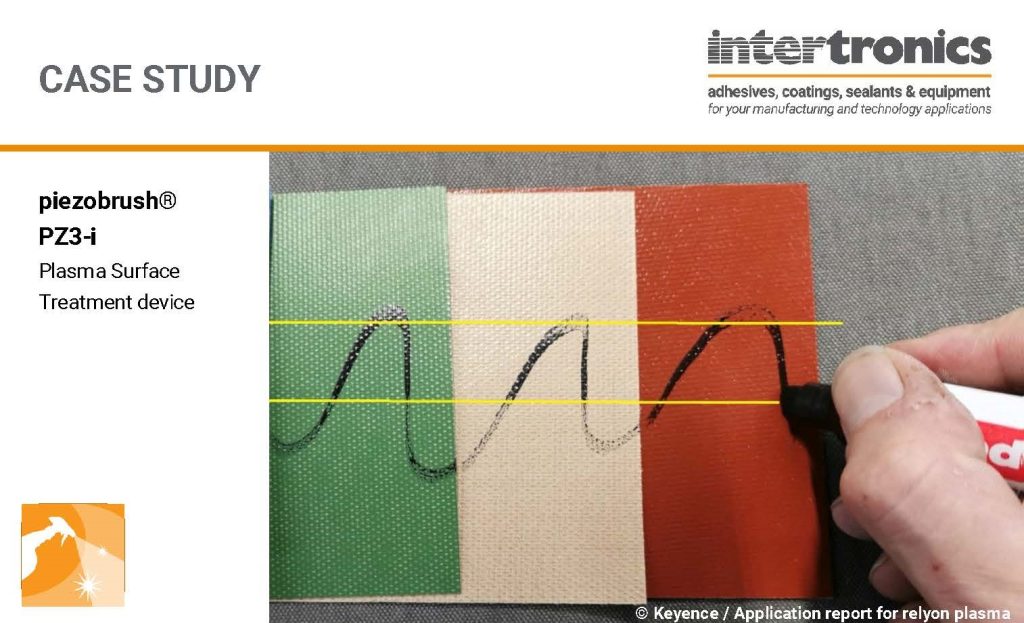

Case study: achieving reliable printing onto PTFE with plasma pre-treatment

Due to PTFE’s extremely low surface energy, it is difficult for materials to wet, and almost no materials or adhesives readily adhere to it. The commonly known brand name of PTFE-based composition is Teflon – yes, the non-stick stuff. However, plasma can be applied to alter the chemical groups on the surface, increase wettability and […]

Read More

Seminar: Improving Adhesion and Bond Quality with Plasma Surface Treatment

We’re delivering a free seminar at the upcoming Engineering Solutions Live show, held on the 23rd of March, entitled Improving Adhesion and Bond Quality with Plasma Surface Treatment. Cold plasma treatment can quickly activate and functionalise the surfaces of many difficult-to-bond substrates, including metals and plastics, whilst removing organic contaminants. This process improves the wetting […]

Read More

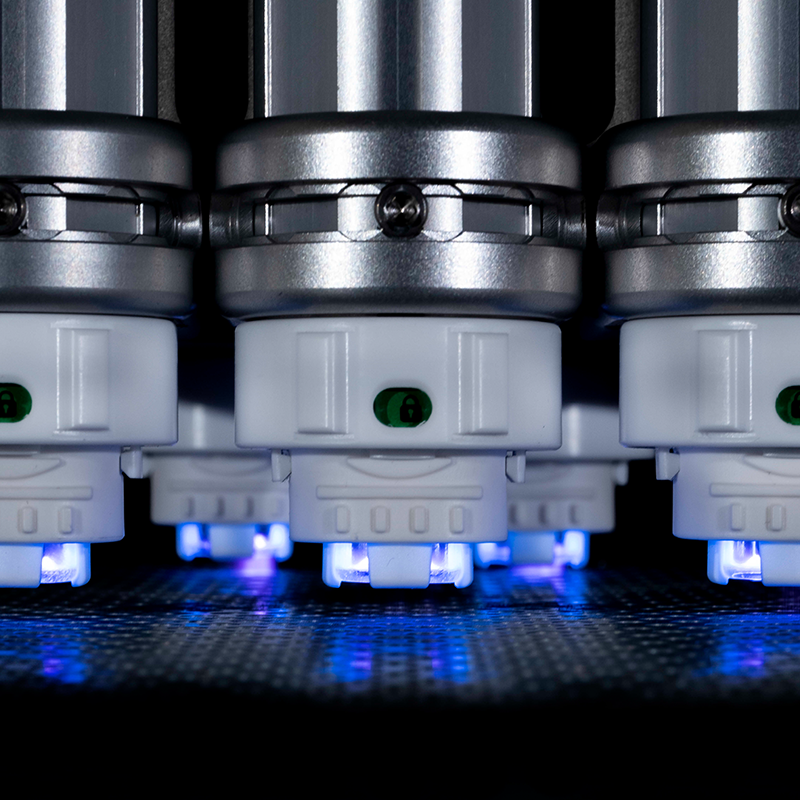

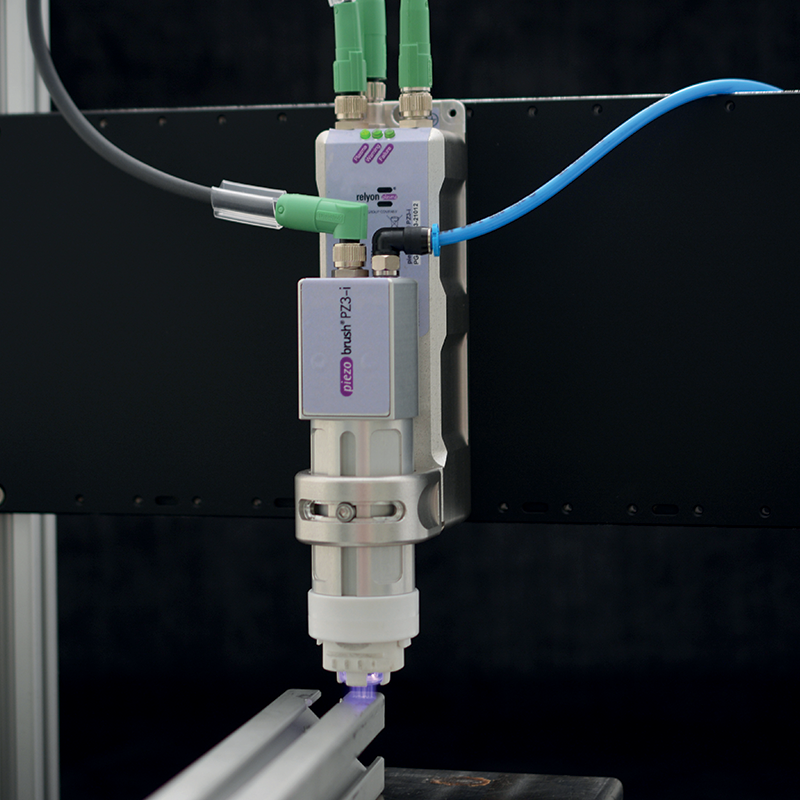

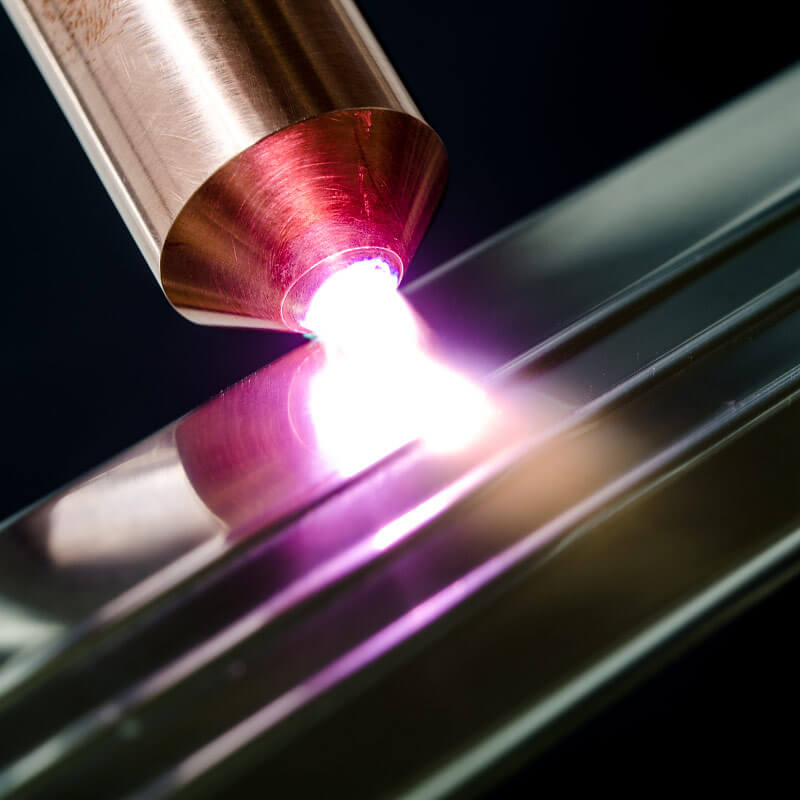

Plasma surface treatment – simple to automate

Providing you with an easy and affordable way to automate plasma surface treatment, the Relyon Plasma PiezoBrush PZ3-i allows simple integration into semi-automated or automated production lines whilst giving you full control over all process variables ─ positioning, power, time, and input gas pressure ─ for a repeatable, controllable, and recordable process. The PiezoBrush PZ3-i is […]

Read More

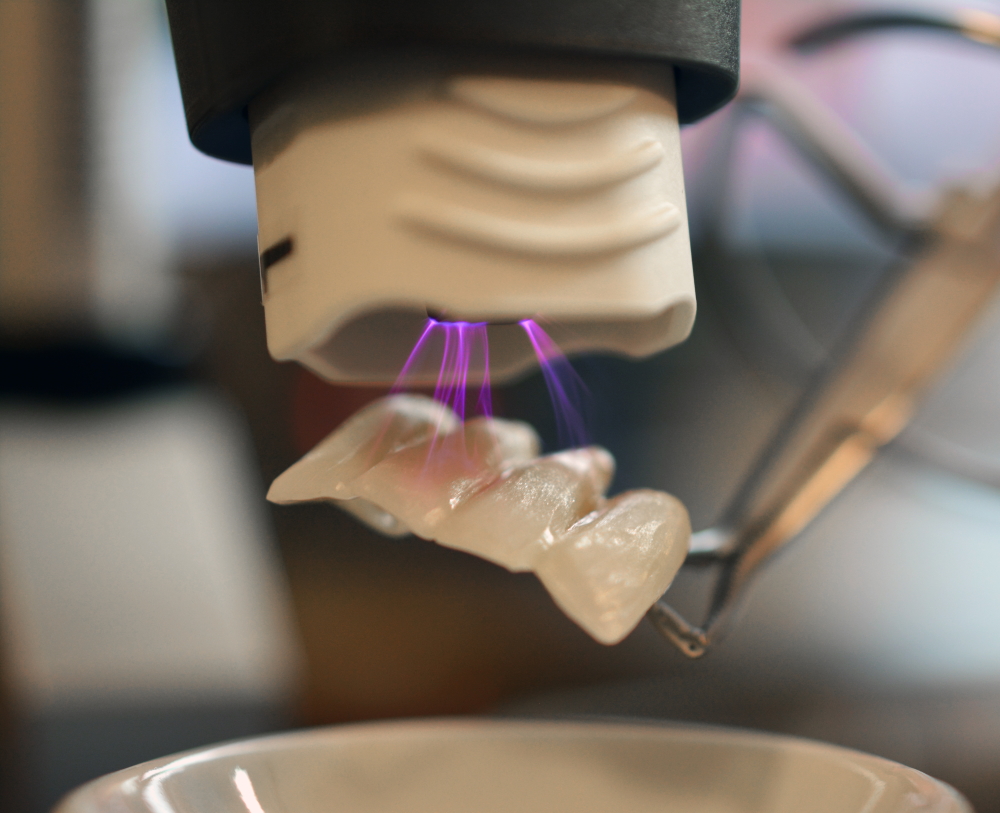

Plasma surface treatment in dental applications offers efficiency and better results

Plasma surface treatment technology is well established in many manufacturing industries including medical devices, electronics, and automotive. In dental technology, several use cases have been developed, researched, and established to help dental technicians perform tasks more efficiently and achieve better results for patients. Plasma can initiate several physical and chemical processes that both clean and […]

Read More

Case study: bonding 3D printed parts

3D printers usually print relatively small stuff – certainly less than 1 meter in any dimension. Our own 3D printer’s largest build dimension is 320mm, and that is fairly common. There are exceptions, of course – these days you can 3D print a two-story house. But for most applications, if you need to make a […]

Read More

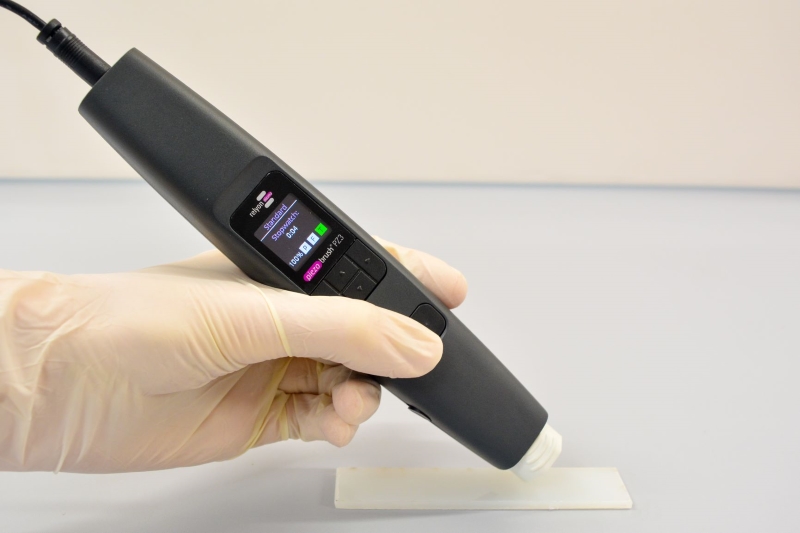

World’s smallest, highly effective handheld plasma treatment device

The PiezoBrush PZ3 Handheld Plasma Surface Treatment Device from Relyon Plasma is suitable for use in manual or semi-automated production, new product development, and in research and development settings such as a laboratories. It is simple, safe and intuitive. With a maximum power consumption of 18W, its unique Piezoelectric Direct Discharge (PDD®) technology is used […]

Read More

Three effective applications of plasma for glass surface pre-treatment

Plasma contains highly reactive species including electrons, ions and free radicals. Application of plasma to glass can make it hydrophilic, increase its surface energy and improve wettability, so that inks, paints or adhesives can wet better. In addition, it can remove organic, inorganic and microbial surface contaminants that form due to exposure to air. It […]

Read More

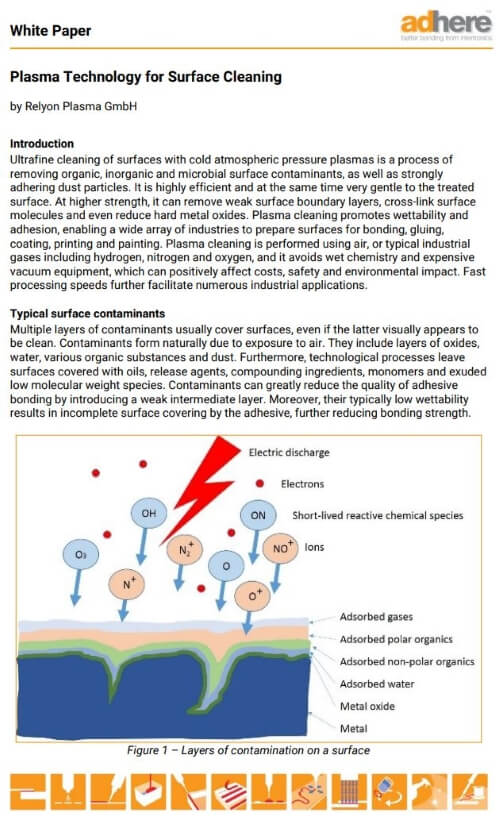

White Paper: Plasma Technology for Surface Cleaning

Whilst our customers typically use plasma technology to improve their bonding, another use of plasma is ultrafine surface cleaning. Relyon Plasma, our sales partner, has produced an in-depth explanation of how plasma technology can clean surfaces, which we have added to our library of technical resources. You can read the White Paper on Plasma Technology […]

Read More

Time to bond with plasma technology

The January/February 2019 issue of Plastic News Europe features our article Time to bond with plasma technology. The piece concludes: “Plasma is not limited to natural phenomena like stars and the Northern Lights. Manufacturers should consider plasma treatment if they are frequently faced with difficult-to-bond substrates. The benefits can be particularly compelling for medical device, […]

Read More