Category: aerospace

Why use a structural adhesive? – adhesives vs mechanical fastenings

In thousands of applications, structural adhesives are being used as a viable alternative to mechanical connections: screws, rivets, or spot welds. The use of adhesives to provide a structural bond can bring many advantages, including improved product performance, reliability improvements, greater design freedom, and reductions in manufacturing costs. Sometimes known as “chemical joining” — to […]

Read More

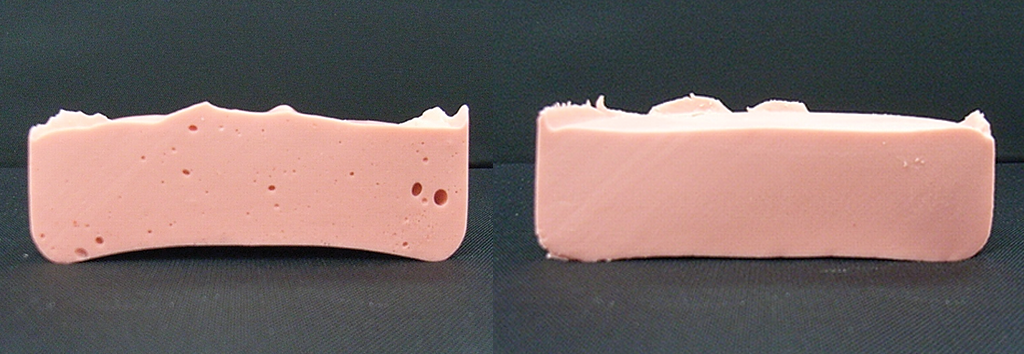

Avoiding voids in aerospace potting applications

Formulators of potting materials for aerospace electronics applications are careful not to supply products with entrapped air. Consequently, entrapped air is usually a processing issue which can compromise thermal conductivity and heat dissipation, or the electrical insulation properties. Voids and delamination can also provide pathways for moisture and other contaminates, weaking the physical structure. If […]

Read More

Case study: SpeedMask – application time reduced from 4 hours to 14 minutes

The masking process at MTU Aero Engines, a leading German manufacturer of military and civil aircraft engines, used to involve tapes, silicone rings, masks and metal covers all manually fitted and applied by operators. So when production planner Thomas Kaltenecker discovered and implemented Dymax SpeedMask, a UV-curing temporary masking liquid, alongside an automated dispensing and […]

Read More

We’re JOSCAR accredited

We are pleased to be accredited and on the JOSCAR supplier register, offering our customers in the aerospace, defence and security industries the confidence of knowing that we meet their high standards of supplier conformance. Using JOSCAR can determine if a supplier is “fit for business”. JOSCAR (Joint Supply Chain Accreditation Registrar) is a collaborative […]

Read More

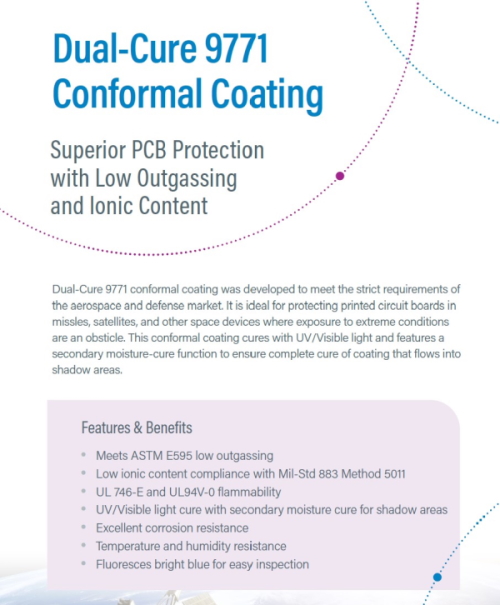

Low outgassing conformal coating meets ASTM E595 & MIL-STD 883

Dymax 9771 Dual-Cure Light and Moisture-Cure Conformal Coating is now available. This low outgassing material is the first conformal coating that meets ASTM E595 and MIL-STD 883 and is therefore suitable for the aerospace and defence markets in applications including missile, satellite, and space critical printed circuit board assemblies. This coating has UL 94 V-0 […]

Read More

Temporary masking compound optimised for UV LED cure

Dymax SpeedMask® 7601 is a high-performance, LED-curable, peelable masking compound formulated for surface protection during plating, anodizing (Type II or III), grit blasting and acid stripping (hydrochloric, nitric and sulfuric solutions) processes. SpeedMask temporary masking compounds are single-part liquids which are readily applied to parts prior to surface treatments. They cure very quickly with UV […]

Read More

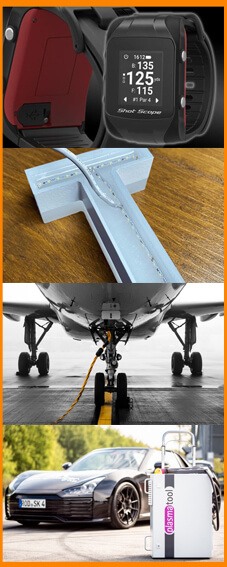

Adhesives in the real world: success stories from our customers

Our customers are doing amazing things, so we’d like to highlight some of their achievements and perhaps provide you with a bit of inspiration for ways to improve your productivity while achieving a great return on investment. Here’s a snapshot of some of our recent case studies: ShotScope has been able to quadruple production of […]

Read More

Case study: improving masking for electroless nickel plating in aerospace and defense applications

An international company who specialise in manufacturing and repairing landing gear and actuation systems for the aerospace market were looking for efficiencies in their electroless nickel plating process – their target was to automate the masking process and increase throughput. The adoption of Dymax SpeedMask brought process times down from as much as three days […]

Read More

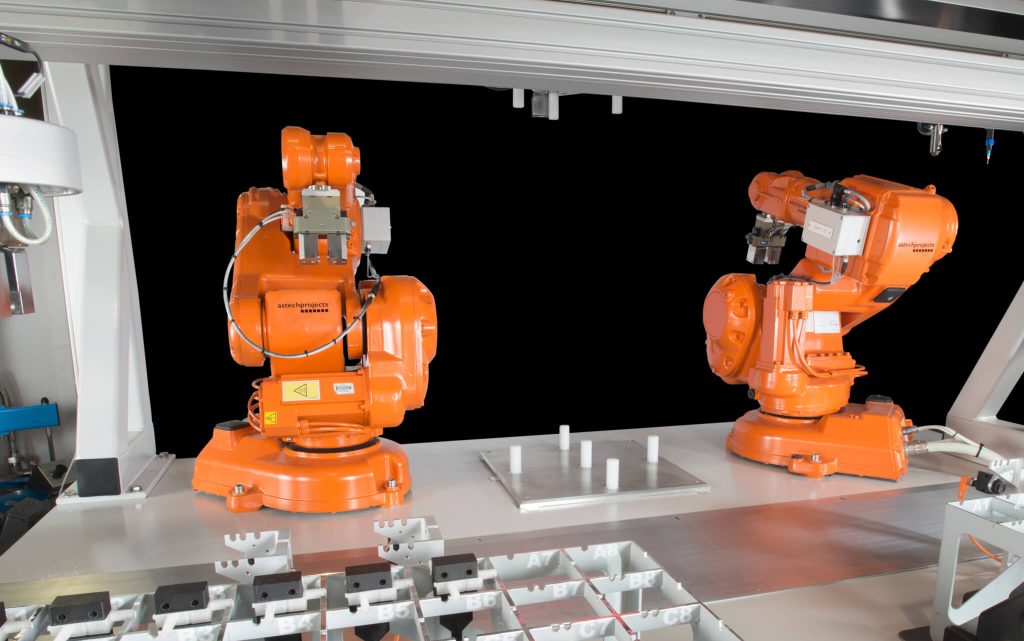

Case study: automation expertise for aerospace temporary masking

The Challenge “A leading UK aerospace company commissioned Astech Projects to build a bespoke Automated Masking System to mask complex areas of aircraft components to avoid precious metal coverage during the manufacturing process,” explained Craig Hamilton, Business Development Manager at Astech Projects. “The system was required to have the capability to mask 14 component variants, […]

Read More

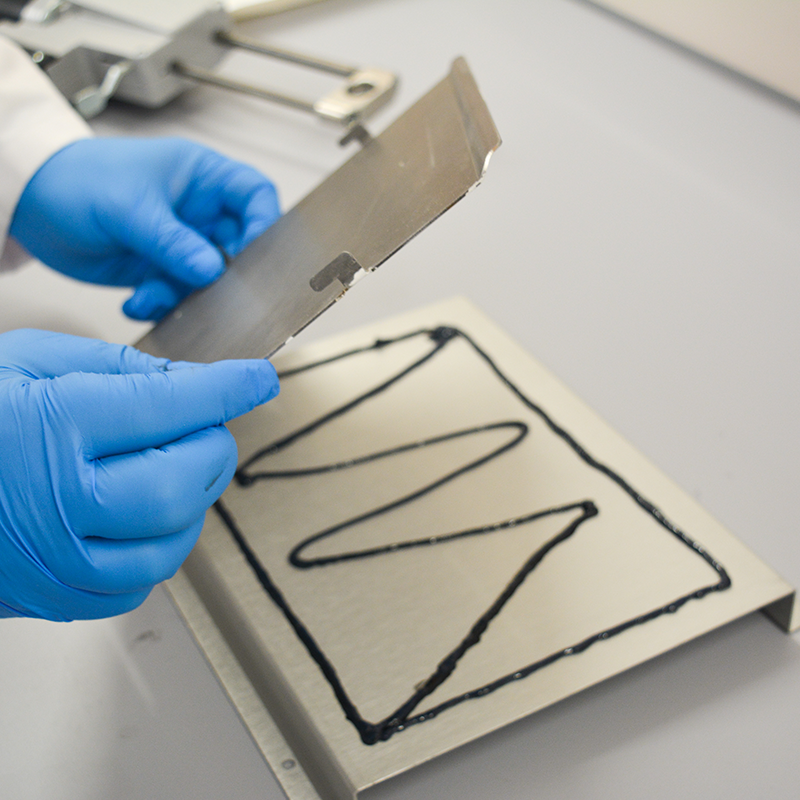

Temporary masking for surface treatment in aerospace

Many harsh surface treatment processes are used during the manufacture of aerospace and other high technology components. During many of these processes, some areas of the component do not require the treatment, requiring temporary protection. Dymax SpeedMask® temporary masking materials provide aerospace manufacturing companies with reliable surface protection without the challenges of traditional masking materials […]

Read More

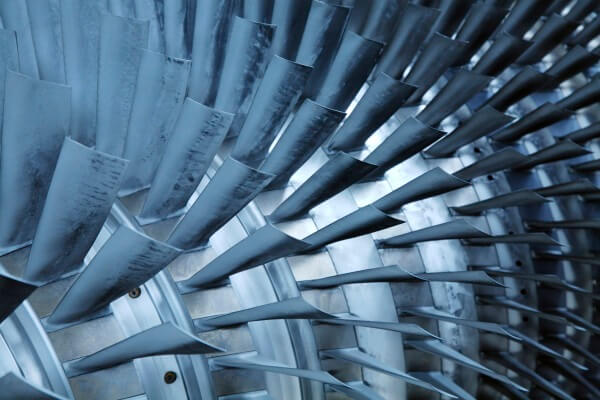

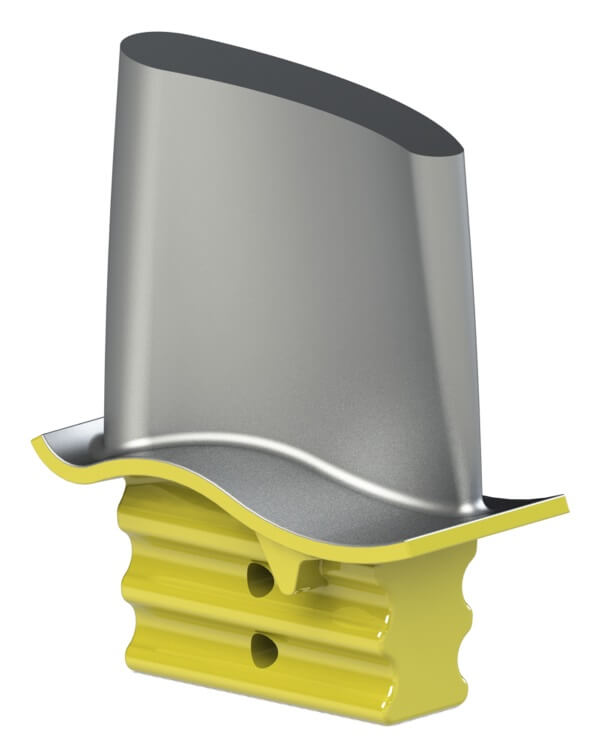

Process protection for turbine components – UV/light cure masking resin

DYMAX Speedmask® 718 UV/light cure masking resin brings the benefits of reliable, quick, effective application and simple removal, to the protection of turbine blades, vanes and other components during specific area surface treatments such as APS and HVOF coating. Protecting areas being left untreated is crucial to high quality outcomes with these maximum performance parts […]

Read More

Advantages of Using Light-Curable Masking for Surface Protection

Dymax SpeedMask® temporary masking resins offer reliable surface protection of components, often more than traditional masking materials such as tapes, lacquers, and waxes. Learn about the advantages of our light-curable maskants in this informative infographic and see a real life example of how switching from thermal tape to a SpeedMask® maskant saved one company 40,000 […]

Read More

Hi Vis temporary mask speeds metal finishing processes

DYMAX Speedmask® 731 speeds up and improves temporary masking prior to aggressive finishing processes in manufacturing, especially on darker colour substrates. Its unique bright yellow colour enables quick and accurate visual checking of coverage or removal which is enhanced by fluorescence under black light. Speedmask 731 is a 100% organic UV/visible curing masking resin which […]

Read More

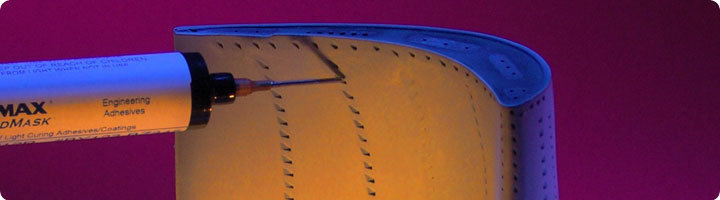

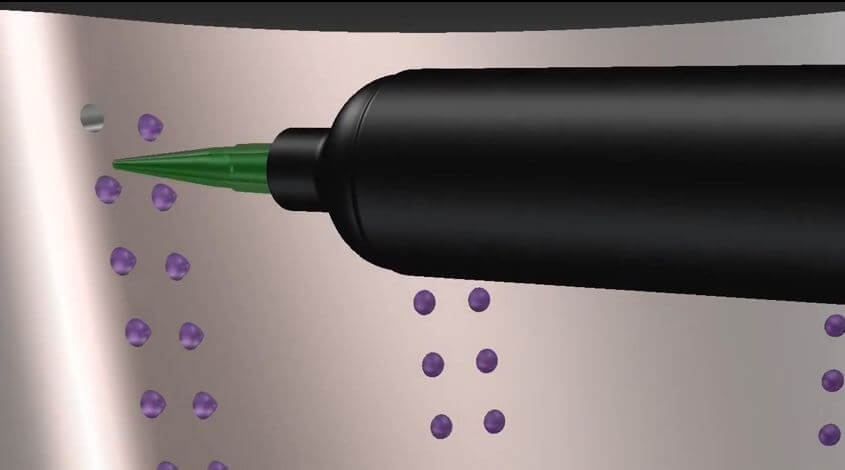

SpeedMask masking resins for turbine blade plasma treatment

Plasma treatment of turbine blades may require effective and efficient masking of the cooling holes during the process – and something that doesn’t compromise the treatment of the surrounding surface. To achieve this, Dymax SpeedMask® temporary masking resin is applied to the cooling holes from a dispensing syringe or through a dispensing valve. The SpeedMask is cured is […]

Read More

Technical article: Customized Masking Solutions

We have just added a new white paper to the Technical Bulletins, White Papers & Articles page on our website entitled – Customized Masking Solutions Don’t Require Customized Masks. Are Your Masking Solutions Failing? The article, written by Virginia Read of Dymax Corporation, discusses masking with conventional methods, the challenges associated with complex design configurations and the need […]

Read More

Temporary masking during acid stripping for aerospace/turbine applications

DYMAX SpeedMask 729 UV/visible light-curable temporary mask provides excellent surface and cavity protection of turbine components during acid-stripping, high-temperature plating processes and other harsh chemical operations. This maskant has been formulated to withstand soaking in hot acid without permeation or seepage under the mask. When cured, the mask provides superior surface protection from chemical processing of nickel […]

Read More

Light weight, low density epoxy potting compound is RF transparent

In some applications the weight of potting electronics to protect mechanically or environmentally can be a very significant part of the overall weight of installed equipment – sometimes this can be a problem. We have come up with some very advanced light-weight epoxy potting technology which brings the density right down to 0.6. IRS 2012 […]

Read More

Heated discussion settled!

Our expertise through the adhere program is becoming well known. Sometimes, we get thrown some interesting (if not always profitable!) questions: I was wondering if it would be possible for you to settle a heated discussion. In which area of the aerospace industry are adhesives used? Is it only composite materials? Or is it also […]

Read More