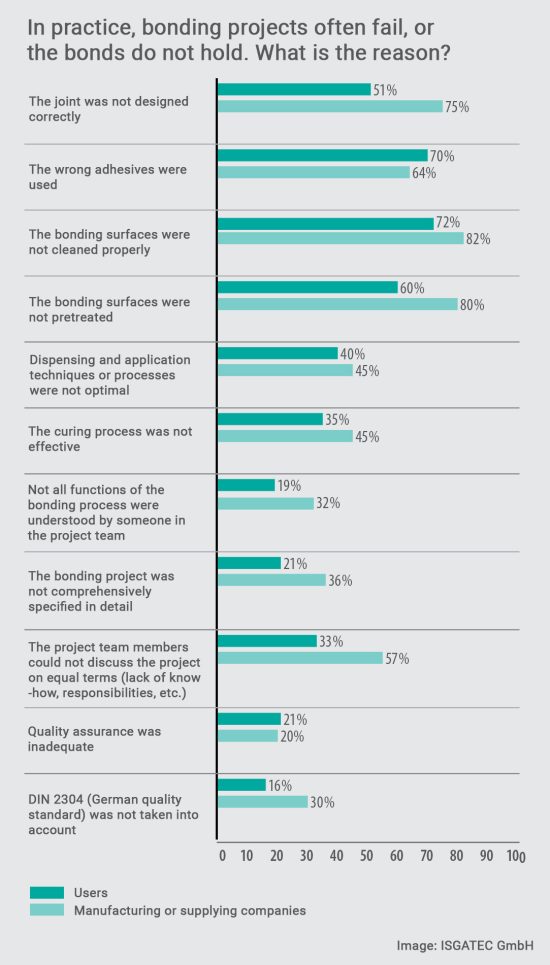

An article in the German trade magazine Dicht! (focused on sealing, bonding and polymers), asked both users and manufacturers of adhesives what the leading causes are of bond failure.

While users and manufacturers had slightly different perspectives and perceptions of adhesive process failure, they are on similar wavelengths. The results present a useful list of things to consider when setting up your own adhesive process, to ensure you achieve the best possible outcome:

What can we learn from this to avoid adhesive process failure?

- Consider your joint design. This User’s Guide to Adhesives has some helpful suggestions.

- Use the right adhesive(s) for your specific application(s). Is the testing and evaluation process robust and comprehensive?

- You may need to clean your substrates before bonding. This may range from a simple isopropyl alcohol wipe (ask us for a free sample!) up to plasma surface treatment for ultra-fine cleaning.

- Pretreat substrates to improve adhesion, if necessary. Plasma surface treatment is effective and not difficult.

- Optimise your dispensing and application techniques. We can help you with this.

- Ensure your adhesive is fully cured. Understanding the curing mechanism is key to this.

- If you don’t have someone in your team who has expertise in adhesives, dispensing/application, curing, or other functions around the adhesives process, make sure your adhesives supplier is knowledgeable, helpful, and responsive. Consider your supplier to be a part of your team!

- Document the details of your adhesive application so that it can be understood by anyone who is involved, including the specification, testing and processes.

- Ensure that team members involved in the bonding process are adequately trained. We offer free adhesive seminars to our customers and prospects.

- Have an effective, documented quality control process.

Our Technical Resources library has a wealth of information on many of these points. If you can’t find what you’re looking for, get in touch and we would be delighted to help!

Categories: adhesives, quality control