I have suffered from the implications of my false economy many times; I expect you have too. Once, I tried to save money on a trip to Frankfurt by purchasing a flight from a low-cost carrier, and landed at “Frankfurt Hahn” airport – 125km from downtown Frankfurt. I ended up paying more for transport overall, not counting the extra time I wasted. This sort of thing easily happens; you buy the cheapest photocopier paper only to find it continually jams the machine.

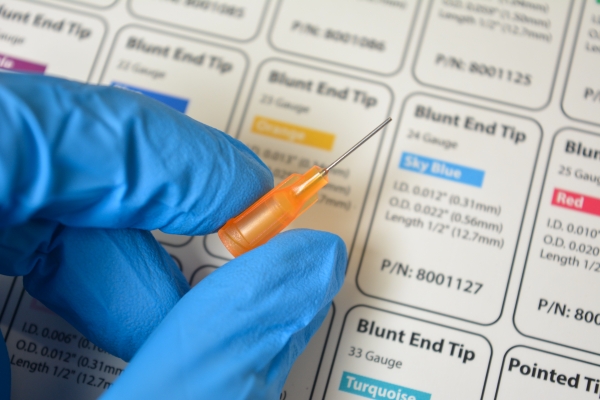

These sorts of false economies can happen when buying dispensing consumables too. Inexpensive dispensing needles, while initially appearing cost-effective, can introduce issues in technology applications like electronics, medical devices, aerospace, defence, and automotive manufacturing.

Can the humble dispensing needle cause you productivity problems?

Can the humble dispensing needle cause you productivity problems?

Here is a breakdown of some potential issues:

Dimensional tolerances

Inconsistent needle inner diameter (ID) or outer diameter (OD) can lead to variability in flow rates or clogging, with the resultant dispensing inaccuracies. Poor mouldings leading to luer lock hubs fitting badly can risk needles coming off in-process, which is certainly messy, and maybe even dangerous to your personnel.

Burrs and rough edges

Poor machining or finishing processes can leave burrs at the output end or rough surfaces inside the needle. Burrs can cause material buildup, clogging, or disruption of flow consistency; can encourage unwanted material flow up the outside of the needle; in some cases, can cause damage to parts, jigs or fixtures. Poor finishing in general can impede material flow.

Frequent clogging

Inconsistent bore dimensions or poor finishes increase the likelihood of clogs, requiring frequent needle cleaning or replacement. Whilst the price of a new dispensing needle may appear low, the actual cost of a premature replacement is added labour, lost production and poor productivity.

Contamination risks

Particulate from machining, poor component material choices, or non-optimal manufacturing practices risks contamination of your product.

Material compatibility

Most needles are bonded to the plastic hubs. Check that the dispensing needles you buy use adhesives which are properly cured, and which stand up to the chemicals which you are dispensing through them, which can be solvating, abrasive or aggressive in some other way.

A good supplier will offer you a wide range of dispnsing needles to suit your exact needs

A good supplier will offer you a wide range of dispnsing needles to suit your exact needs

I suspect that these problems don’t occur every day. Maybe the effects are inconsequential on a daily basis but build up incrementally over time. When they do, the costs associated with loss of production, scrapped parts, material wastage, and your time outweigh the purchase savings. Investing in dispensing needles and other consumables of known quality from one of the respected brands will keep your productivity levels up.

I’m just off to unjam the photocopier…

Posted by Peter Swanson

Peter is the Founder and Executive Chair of Intertronics. He is mostly involved in strategy, recruitment and helping out the Marketing team.

Who's Peter?Categories: dispensing, productivity